Story

While designing and planning the New

Decks for our house, I decided to make custom deck furniture. This

was an ambitious plan as I enumerated all the pieces I wanted. To make

it more manageable, I limited the first set of furniture I built, which

you can read about on the Phase I

Deck Furniture Project Page. After the basic benches and tables in

the first phase were completed a number of other pieces I built in

sequence. I've grouped all these subsequent pieces into this one

project page, and labeled it as "Phase II" of the overall deck

furniture plan.

This Phase II work consisted of the following:

- dining table;

- chairs and side table for covered porch;

- work bench and cabinet; and

- clothes/towel rack.

For both the Deck Screen and Phase I Deck Furniture, I had

ordered a large amount of lumber, but this was not enough to cover all

the Phase II furniture needs. There was enough left-over lumber to

start, but I needed a second order so I had to plan out all the

upcoming projects so I would only need to pay for a single delivery

charge. The order consisted of pressure treated lumber for the

underlying (non-visible) frames, Ipe wood (same as deck) for the

wearable surfaces and cedar for the "skirting" that hides the

frames. This lumber also included boards for the a planned project

of adding some stairs around the pool. Planning this was very tricky

since I had just a rudimentary idea of what I wanted here, and in fact

I wound up changing my mind about using the wood for that. Instead,

that area became the Deck Perimeter Project and

this would would eventually be used for the Outdoor Planters Project.

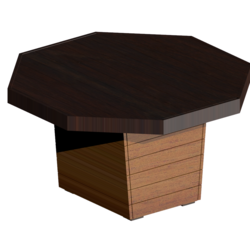

Dining Table

My original plans called for bar-height tables. This was not going

over so well with the other half, and I eventually began to doubt this

being a good option. BY the time I had completed the Phase I Furniture, I had changed

the plan to have a traditional height dining surface. With the ease of

cutting angles that my new-ish miter saw gave me, and wanting to break

out of the square table mode a bit, I decided to design an octogonal

table.

I did some initial sketches on paper while on vacation and then moved

onto making a 3-D model to better work out the geometry and get more

precise about the dimensions for everything.

In terms of chairs for this table, I decided to purchase chairs as a

short-term plan, since I did not want the queue of projects to grow and

I did not have good ideas for making chairs any better than what I

might find I could buy.

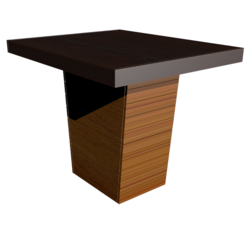

Porch Furniture: Seats and Side Table

When we moved into the house (14 years ago), we inherited patio

furniture that included a love seat sized bench that swings a bit. This

sits under the porch so is a nice place to sit, no matter what the

weather. This bench was in need of replacing, so I decided to make a

couple seats to replace this that would match the rest of the deck

furniture. I also wanted to add a side table as that is always handy

when you are sitting. For the chairs, I just made smaller versions of

the deck benches I designed and built for the Phase I Deck Furniture

Project. For the table, I just made one more of the smaller side

tables I had already made for the deck furniture. I had all the

templates I needed to make these quickly and the design had proven to

be comfortable.

When I was designing the benches, I had actually made a smaller

prototype out of materials I had lying around. This was a bench that

was only 2 feet long, which had the effect of being a chair. This

prototype sat in my shop (a.k.a., garage) for months during the process

of building all the other furniture and I used it constantly as a

comfortable resting place. I needed two chairs for the porch, so I

decided to re-use the frame of the prototype for one of these chairs.

The frame was the only thing that was made of the right materials

(pressure treated wood). I did have to replace the screws with the

drywall screws I originally used with some stainless steel ones for

outdoor use.

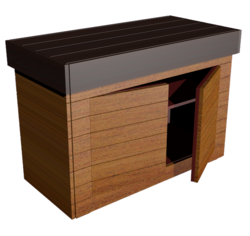

Work Table and Cabinet

I wanted a work-height table in the backyard so I could work closer to

where a lot of the outdoor projects tend to take place. The outdoor

projects (i.e., pool pump repair, lawn mower repairs) tend to be

unplanned, and as such, the work bench in my garage is often occupied

with something else, and it is also a hassle to maneuver clunking

equipment if the cars are in the garage.

My wife had also suggested adding some cabinets for storage, which

wound up being a great idea. Projects tend to span days, so having a

place to stash tools and such overnight would be handier than dragging

them all back into the garage.

All the other furniture has one side sloped in at a 5 degree angle.

This is purposeful for the benches for the right ergonomics, but it is

a stylistic things on the other pieces of deck furniture. I tried to

carry this theme over to thsi work bench, but an angle greatly

complicated the structure when having to support swinging doors. I

finally gave up and sacrificed better visual appeal for the more

practical goal of keeping the design simple.

The octogon dining table was relatively similar in design to the side

tables I had made a lot of, so there were only minor issues to work out

when trying to move from the 3-D model to actually building it. The

porch chairs and table were even less eventful since they were so

similar to the previously built pieces. This work table however, was

very eventful in terms of having to figure out a lot of unforseen

issues.

The first adapation was for adding an additional support on the top of

the frame. The span of the surface boards would be too long otherwise:

something I did not think about during the design phase.

Besides having cut out the doors and having a 2x4 vertical frame piece

to mount them on, none of the details of how the hinging of the doors

were worked ou. I needed stainless steel hinges to survive outdoors

and none of the local places seemed to have such a thing, so I resorted

to Amazon. This meant waiting for the parts to arrive before I would

know exactly how to lay out the rest of the project.

The stainless hinges I found were not the highest quality items, and I

would need to use my own stainless screws for them instead of the

non-weatherproof ones that came with it. However, oevrall, the hinges

would do the job.

On top of the door surface, and on top of the entire frame would be a

layer of cedar "skirting", which would make it match all the other deck

furniture. At this point, I knew there would be some tricky issues to

work out regarding the way the door hinged and the addition of a 3/4"

thick piece of cedar. As it was now, the doors hinged nicely and were

flush to the frame, but the cedar would get in the way, so something

would have to be worked out. The hinge design was such that you could

see some of it, or at least the simple way I chose to cut out the wood

did this. I would want to hide that in the finished result with the

cedar somehow.

Another big difference between this work table and all the other

furniture was that I wanted the interior to be somewhat protected from

the elements. With the other furniture, all the surface wood has 1/8"

gaps so water and smal debris can just fall through and generally would

wind up on the ground. With the cabinet, I would want to be able to

store things in here without them getting soaked. I also did not want

any animals crawling in and making it their home.

What I did was to add a shell of plywood to this frame to created a

closed compartment for the entire interior. Here is were I ran into a

couple other design flaws. I did not think about how I would need to

secured the back plywood to the the existing bottom and middle shelves,

and thus needed to add shims to get them flush. I also had nothing to

adhere the back plywood to in the top middle part, so I had to

improvise an additional support piece.

With the door installed, and all the plywood encasing in place, I then

took some silicone sealant and went to town. I try to imagine I was

water and think about where I would go, and I plugged up every place I

find that I thought would admit water. I also coated the entire top

surface plywood with a layer of silicone. The surface will have Ipe

wood with 1/8" gaps, so water will go in and sit on top of the plywood.

Though it was stained andn sealed, I still did not trust this would

last as long as I would like, so I hope this silicone layer will help

that. Note that the silicone in the picture is white, but it dries

clear. None of this silicone will be visible though, so it did not

matter so much.

I was now ready to tackle the issue with how to dress up the frame with

the cedar skirting, while still allowing the doors to swing open. I

originally though all I needed to do was to put a 45 degree bevel on

the door and the post side. However, I found that this would have only

worked if the door hinged exactly along the border, which it did not.

Instead, the doors swing completely clear of the opening, which meant

coming up with some other solution. During the day, I tried a few

different ideas. Some would not work, be too complicated or result in

an unsatisfactory appearance. Nothing was resolved. Later that night,

going back into the shop to ponder this some more (after some

incubation period), I came up with a reasonably good solution.

When the doors swing out, there is about a 3/16" clearance, so I used

my router table to create a cedar skirting piece that was very thin in

one part. This would hide the hinge and visually match the horizontal

cedar look. There would be abit of an indentation, but that wound up

not being all that visually unappealing.

With the door hinging problem solved, I could now install the cedar

skirting. I wanted the horizontal lines between the cedar pieces to be

aligned all the way around the cabinet, and since the doors were the

place where things had to line up more precisely, I had to install the

cedar on the doors first.

I decided to screw the cedar in from the back instead of from the front

like all the other cedar was. I think visually this is better, but the

real reasons had to do with the available fasteners I had. I had

1-5/8" screws I used for the cedar, and these would be too long to go

into 3/4" cedar and the 1/2" plywood door. I also has 1,000 stainless

steel screws (#6) that were 1-1/4" long which results from my not

checking carefully when I meant to order 100. I had been using these

screws every chance I got.

At this point I thought I was home-free and there were no more

unforeseen issues to be tackled. Of course, I was wrong. The front

upper pieces of cedar, similar to the back plywood, had nothing to

adhere to in the middle, making it too wobbly for me. I added an

identical support piece to the one I improvised for the back plywood.

I had originally not planned to add cedar skirting to the back of the

cabinet, but during my late nigfht inspirational session, chnaged my

mind. The result was that then bottom back cedar piece had nothing to

adhere to that would keep it flush with the rest of the boards. I had

to add a couple shims to compensate.

After the cedar skirting assembly, I started to get a real

understanding of an unforeseen implication of my design. This cabinet

was very heavy. It was already heavier than I could manage, and likely

heavier than my wife and I could manage. This was before we added the

very, very heavy Ipe wood to it. I'd likely have to get my very strong

friend to help me.

The final unforeseen problem I ran into was conflicting screw

locations. I had already pre-drilled the holes in the Ipe surface

boards (which you need to do because this wood is so dense) and had not

considered the places where they might conflict with existing screws

that were part of the frame and plywood encasing. I did run into a few

conflicts, but was able to redirect the screws at a slight angle to

avoid the collision. This was preferrable to having to drill another

hole, or having to cut another board. Here's the final result:

The work table sat in my garage for a few days while I waited to ask my

friend to have time to help me. I was not in any rush, so did put it

out of my mind while I worked on the next project. Then, one day, as I

was sitting around, I got inspired. The very beginning of this whole

series of deck-related projects was when I had to get rid of the very

heavy broken spa that was on the old decks. You can read about that on

the New Decks Project

Page.

I had learned a few tricks watching that crew move the spa, and I

thought about how I might be able to move this work table all by myself

using those tricks. The challenge of doing it became too enticing, so

I decided to give it a try. I also got the romatic notion that the

project's beginning and ending should be tied together somehow. This

piece of deck furniture was the last major piece of the 3 month long

series of projects.

I had a couple 12 foot 2x6 boards lying around, and a couple 3 foot

long round dowels (which were in fact the exact ones the spa removal

crew used). I could just push this up an improvised ramp on these

rollers, and with the help of some furniture dollies to move it on flat

ground, it turned out to be relatively simple to get this thing in

place.

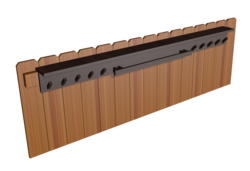

Clothes/Towel Rack

One obvious flaw with the new decks and deck furniture was the lack of

having a place to hang wet clothes and towels. We have a pool and

outdoor shower, so the need to have a place to put things became very

clear when we first used the deck area for its intended purpose. The

first step was to figure out a good place to hang things, which my wife

came up with. The next step was to design something that would fit in

that area, be easy to make, would fit into the decor and would not

require anything but lumber I had lying around. I googled around

images of towel and coat racks for inspiration and came up with the

design at right. Simple, easy to make, and providing ample places for

things. I would make it out of the Ipe I had lying around to match the

furniture and decks. One of the inspirations I got was to also add a

ledge above the hooks to allow putting small items down (phones,

glasses, etc.)

From the time I was in my pool with my wife discussing the need for

some rack, until the time is was installed was less than 24 hours. I

had designed it later that afternoon, and was able to build it the

following morning. It wound up improving the deck not just by adding

needed functionality, but the fence it was put on was a bit of a blank,

empty-looking thing. The addition of this rack makes it look like the

fence has a purpose.

The LED strip lights run under the same 3x4 that this rack was

installed on. This was my first concern when my wife proposed this

location, but by using a 1x6 board on top of the 2x4, it actually

protects the light, while still allowing it to light up the ground in

that area. It does block the light a bit higher up, but in this area,

the need for light at a higher level is minimal.

Cassandra.org

Cassandra.org