Story

In our house, there is a large closet just off the kitchen that one of

the previous owners used as a sewing closet. It has a few, narrow

shelves up high, and a sewing desk with drawers such that with the two

closet doors open you can sit at the desk and sew. Not having much

sewing to do ourselves, this closet stored our games, light bulbs and a

lot of work-related miscellany. Back when I wired the house with cat 5e

cable to all the rooms many years ago, this closet is where I

terminated all the cables. Thus, this became the network closet with

the main Ethernet switch as well as the cable modem, router and

wireless access point.

More recently, when I did the Home Theater

Project I also put all the home theater equipment in this

closet. While functional, it became a bit of a mess in there, and with

my wanting to move the servers from the Home Server Build Project

in there, it was time to reconfigure this closet to be more functional

as a server and storage closet than a sewing closet. This page

describes the conversion of the closet.

Overview

Now, let me first address the question you might be asking yourself:

-

"How does cleaning your closet turn into something you call a

"project"?

- Demolition of the old sewing desk and (way too small) shelves;

- Relocation of the electrical outlets;

- Relocation of all the Ethernet cables;

- Relocation of all the home theater cabling;

- Adding additional support structures to support the new shelves;

- Adding adjustable and movable shelves for easy access to the connections on the back of the computers and home theater equipment;

- Installation of a vent and temperature-controlled fan in the wall for cooling;

- Addition of internal lighting and switch;

- Mounting a monitor and keyboard tray for ability to work on servers;

- Building a new cabinet for storage;

Requirements and Specifications

The things the server closet will need to have room to contain:

- Main house server (cameras, SSH, OpenVPN, web server)

- Network storage server (backups and shared files, images, movies, music)

- Home Theater server (currently a Mac Mini)

- Audio/Video Receiver (currently an Onkyo)

- Cable Modem

- UPS (uninterruptable power supply)

- Router/Wireless AP (currently an AirPort Extreme)

- 24 Port of Gigabit Ethernet switch

- 4 Port POE Ethernet switch (for cameras)

- HDHomeRun (converts TV over antenna to IP stream)

- VCR (yes, long story)

- Small LCD Monitor (for working on servers)

- Keyboard/mouse for working on servers

- Games

- Teaching supplies

- Light bulbs

- Miscellaneous, undetermined stuff

The features the server closet should have:

- Good air flow/cooling (maybe remote temperature sensor)

- Good cable management

- Place to mount two double outlets for all the house Ethernet ports (RJ-45)

- Place to mount HDMI single outlet

- Place to mount double outlet for home theater speaker wires

- Place to mount single outlet for extra speaker wires

- Making rear of components easily accessible and visible

- Extra shelf space for non tech things

- Drawers for non tech things

- Shelves should be adjustable height

Initial (abandoned) Design

My original plan was to have a section of shelves that would completely

swing out as the way to get full and easy access to the rear of the

electronic components. I did all sorts of research on the strengths of

hinges that would be needed to support the weight of the components and

figured 4 or 5 door hinges would easily suffice.

However the complication was that this would have to lie on an

infrastructure that could also support that load, which effectively means

that the shelving structure would have to be part of the main house

framing. If the existing studs were in the exact locations I needed for

the dimensions of the shelves I needed, this would not have been too bad,

but the odds of that were low, and the reality of their locations meant I

would need to open up 3 walls and the ceiling to be able to build a

suitable frame.

As I was designing such a structure and mapping out the work, this

creeping thought started to gnaw at me: Might I spend more time

building this structure than the time it will save me from the

inconvenience of a slightly inferior solution? After some time, the

answer to this question became quite clear, though I am sure it would

have been clear to saner people much sooner than it did to me. I was a

little bit enamored with the swing-out shelf idea.

Design

Instead of swing-out shelves, I decided I would add a few sliding

shelves. This would not be ideal, but would make it a bit easier than if

the shelves were fixed. Interestingly, once I turned to this decision,

the entire design of the closet came to me in an instant, and the

resulting solution became super simple to build (conceptually). There's

still a lot of work to do, but there was little uncertainty to how I would

build the shelves and cabinet and that this would work with minimal

surprises.

Now being on the track of simpler solutions, I also abandoned my initial

idea of having a built-in cabinet and opted for stand-alone cabinet that

would slide into the closet. That wound up being a separate project I

call the Closet Cabinet

Project.

The Planning Phase

I mostly planned this before I was back home full-time when I was

visiting for a couple weeks. The plans are also a derivation of the

initial ideas I sketched when planning to have swing-out shelves. The

final result is close to this, but not exactly like this. These

sketches also reflect some of the changes I made as I went along and

faced various surprises and unforeseen constraints.

The Waiting Game

Besides the finishing (sanding and painting), the Closet Cabinet was

completed first as I waited for my wife to have time to go through and

empty the closet of her things. I was also busy with the design work

on the New Decks Project while I

waited. However, while working on the cabinet, I rough cut all the

pieces I will need for the shelving and bought the rails for the

sliding shelves. I wanted to combine all the final sanding and

painting because both these steps require me to reconfigure my workshop

(a.k.a., the garage). You do not want lots of sawdust floating around

while painting.

Preparation

The first complexity was how to keep the Internet connection working

during the duration of the project. We could live without the

home theater equipment, but not the Internet and I did not want to do

any major re-routing of wires. The plan was to pare it down to the

absolute minimum I would need and try to run all the cables to a nearby

table. I slowly began to disconnect and remove the non-essential

components and cables, which was a bit of a discovery process since I

had not thought about exactly what was and was not critical parts of

the infrastructure. This did help me plan the future setup in terms of

what did and did not need to be on backup power (on a UPS).

For the most part, I was able to route the cables out of the closet to

a nearby table, but there were a few wires that were not long enough to

reach. I did not have the cables to lengthen their reach, nor did I

want to invest in them and/or wait for them to be delivered. I had to

improvise a solution by hanging a switch on the top of the door. I

used some old shelf brackets, tapped some holes for screws and added

some padding so it would not scratch the door. On the nearby table

where I assembled all the network gear, I ran an extension cable to

power it from a different room. I would need to be doing electrical

work in the closet and I did not want to have to be without the

Internet while I had the closet circuit breaker off.

The Demolition

After the closet was cleared out and the temporary wiring changes, it

was time to begin the physical work, starting with removing the old

desk and shelves. Surprisingly, the shelves were held up by exactly

two nails. I am not a fan of nails and I would never think to use only

two nails for any entire shelf assembly, but the shelves were still

standing and the nails were not so easy to remove. I tend to

over-engineer structural things.

A Simple Start

Next came removal of the wall boards in the area where the wiring would

be. This needed to be done because I was going to be adding additional

wiring access and also because I needed more visibility into the wall

structure to help refine the plans for installing the shelving. One

surprise I found after removing the old desk was that there was another

electrical outlet behind the desk. There already was an electrical

outlet in the closet on the right side wall, and it was only a couple

feet away from this discovered one. The desk drawers made this outlet

inaccessible, so I suspect that they added the second one after the

fact once they realized the mistake. Two electrical outlets in a

closet otherwise does not make sense. Fortunately though, this

actually simplified the electrical work I needed to do (for the

moment). If I added a junction box where this hidden outlet was, I

could easily add a new outlet higher up on the same wall with little

effort since I already had the wall open.

The Demolition Escalates

My initial plan for supporting the shelves was to screw in some pieces

of plywood to the studs. I did not like this solution because that

leaves you with a "wallboard sandwich" where there is a (useless) piece

of wall board between the studs and the plywood. I also realized I

needed to open up more of the wall to see how to affix the center shelf

support. It was this point in the project where I saw a path toward

incremental escalation and decided to meet it head on and strip the

entire closet of wall board (except the lower part). There would be no

piecemeal surprises and I would have a solid plywood on stud support

structure.

Additional Electrical Work

The outlet I move up was to be used as the main one to power all the

equipment, but I planned to add some form of lighting solution and the

cooling fans. Both the lights and fans would be located near the top

of the closet and I preferred not to have a long cable run and

additional cable congestion. So on the right side wall, I added an

outlet about 6 feet off the ground, where the bottom outlet would be

controlled by a switch. The switched outlet would allow me more

flexibility on lighting solutions, which I only had a vague idea about

at this time.

Shelf Support Structure

With all the behind-the-wall electrical work done, I was ready to add

the most critical pieces of the project: the shelf support structure.

Half-inch plywood against two walls and a central piece of

three-quarter-inch plywood would be taking the full weight of what

would be on a total of 12 shelves. Putting plywood on the side wall

studs was simple, but I needed a more clever solution for the central

support. I used a dado joint on a strip of wood so that I could attach

the support to this strip and then easily nail the strip to the

studs. I also added a similar strip to the top to be able to screw into

the ceiling joist for added support. The shelf brackets will fail long

before my shelf support structure does.

You will notice that the center support is tapered, which matches the

decreasing shelf widths as you go upwards. This is part of the design

because with the door not going to the ceiling, getting things on the

top shelves require maneuvering room. Originally, the design had the

two side plywood pieces in the same tapered shape, but I decided it

would greatly simplify the sheet-rock work if I just used rectangular

pieces instead. The trickiest part of installing the center support was

ensuring that it was level and straight. Since the plan was to have

sliding shelves, if the center support and the wall were not parallel,

a sliding shelf would not work: you cannot (easily) build a sliding

trapezoid. here the complications though:

- the walls themselves are not parallel;

- the center support plywood is slightly bowed; and

- the furthest protruding part of the center support needs some side-to-side movement stability.

Note that the other main benefit of having plywood on

the wall was to add flexibility for mounting anything else that would be

needed without having to worry about finding a stud.

Fan Boxes

When I first put the cable modem and network switches in this closet, I

put them on a high shelf because that was closer to where they came in

on the ceiling and I also wanted them to be as out of the way as

possible. Because the heat generated would get trapped, over the years

I burned out two different Linksys switches. I move that equipment to

a lower shelf and that helped a lot. But the addition of the home

theater receiver and a new cable modem only added more heat to the

closet. With my plan of moving two servers into this closet, I had

to have a cooling solution.

I found a nice simple temperature

controlled fan controller and with help from my wife decided to add

both an inflow and outflow to promote good airflow. This mean poking

two holes in the wall, and trying to do so in as non-intrusive a way as

possible. I also wanted to ensure that the fans sucked the air from

the closet and not from inside the walls. Thus, I created simple

plywood boxes to channel the air.

Access Panels

Once I had the walls opened and contemplated the annoyances I always

face when adding wires to this closet, I decided to make my future work

simpler by putting in hinged access panels instead of mounting things

to the wall. The patch panel plates would mount to a door that could

be open and closed to get at the back side of them as well as providing

a wide access to wall cavity to more easily find cable drops.

The tricky part here was making the access panels big enough to house

all the needed cables, but located so that opening and closing them did

not interfere with the shelves. I was hoping to have room to have space

for expansion, but under the constraints, it was all I could do to

provide the space for the already needed wiring.

Wallboard Installation

With all the electrical work, support structure, fan boxes and access

panels in place, it was time to cover what remained with wallboard.

This is always the turning point of a project. For the first time you

can start to see the final result begin to take shape: the solution

turns from crude pieces to a more coordinated and refined whole.

Although the fan boxes where installed, I had never actually poked

through the wallboard to the external side. I wanted to wait until the

last possible second before I made changes that were visible outside

the closet. Wanting to wrap up all the sheet-rock work0, now was the

time to take the plunge.

Change of Plans

The original design for the left-hand side of the closet was for every

shelf to be adjustable. To address the center support issues of

straightness and stability, I decided to make one of the shelves fixed

to prevent side-to-side movement of the center support as well as

giving a straight anchoring edge to help anchor and flatten out the bow

in the wood. The hope was that adding this one fixed shelf would

straighten out the bow enough, and though it helped, I also had to add

another fixed shelf higher up to fully fix the problem. An important

lesson is to always use straight wood. I should have known better from

past experiences, but missed this somewhere along the line.

Sliding Shelves Installation

With the center support now installed, semi-straight and fully stable,

I moved onto getting the true final dimensions I would need for the

sliding shelves. For the adjustable shelves, there is plenty of slack

to work with on the shelf widths, but the sliding shelves need to be

fairly exact. One mistake I made in my first design was to not account

for the fact that the door jamb of the closet is actually a couple

inches out from the wall. Thus, if you were to have a sliding shelf

flush with the wall (as my first design did), you would hit the door

jamb and not be able to slide the shelves further. I caught this in the

design phase though so knew I had to make some form of offset for these

shelves. I glued 3 pieces of 3/4" plywood to create a 2-1/4" offset,

which would be enough to clear the door jamb.

Trying to maximize shelf space and keep things clean looking, I had the

shelf surface overhang the sliding rail mechanism. The tolerances on

all this needed to be very close, no more than a sixteenth of an inch

off. However, there was still an unsolved problem: the wall and the

center support were not perfectly parallel and not perfectly flat.

This meant that the actual distances between the front and back of a

shelf were not the same and it also meant that not all shelves would be

the exact same width. Making each shelf custom to the actual

dimensions was not a big issue, but a width difference for the same

shelf between front and back was unacceptable. Despite the addition of

the fixed shelves, there was still a 3/16" discrepancy on individual

shelves, which was too much. Since I had an individual piece of wood

being used for the offsets, I decided that if I could taper the

offsets, then that would bring the center support and the offset

parallel. There was lots of measuring and re-measuring and some tricky

table saw cuts, but I managed to get a taper good enough to be usable.

Adjustable Shelf Installation

The installation of the adjustable shelves was relatively

straightforward. Main keys are to ensure the brackets are level with

one another (and not the floor or ceiling) and that they are in good

positions so the shelves do not "tip". Because the shelves are of

varying widths, in some places, there was no single spacing of brackets

that would provide a stable shelf, so I used multiple brackets to allow

more flexibility in location and stability.

I had rough cut the shelves over a month before and allowed and extra

inch in both directions. Because of some surprises I found on the stud

locations, the center support was not exactly where I planned it to be,

but was slightly further to the right. Luckily, the left-hand six

shelves were still long enough, though not by much. I made the final

width cuts on all the adjustable shelves and installed them all to see

how they fit.

Network Re-routing

The day I was dreading had come: it was time to move all the network

cables from their current hard-to-access ceiling location to the new

wall access panel location. Why the trepidation?

- working in the corner of the closet ceiling is a pain;

- new A/C duct work we did made the wires and entry point hard to get to from the attic side;

- the wires had become a tangled mess and things were incrementally added over the years;

- I would have to be up in the (hot, itchy) attic for a few hours untangling cables: and

- I would be without Internet access until everything was moved.

It turned out to be better than I expected, but maybe mostly because I

expected a nightmare. It was for the most part uneventful, which I was

thankful for, and everything still worked after the move. However, with

all the cables moved downward, they no longer reached to the switch

mounted at the top of the door, so I had to do another reshuffling of

the network components. I wouldn't be able to hook everything up for

good until the very end.

Wallpaper Removal

I did not remove the lower 3 feet or so of wallboard since that was not

needed for the shelves. But this wall did have two layers of wallpaper

on it that I wanted to remove before finishing the walls. The old

wallpaper was semi-ugly and came off relatively easily. The older

wallpaper below it though was hideous and was a known headache to

remove (from my wife's previous experience in the neighboring hallway.

The whole time I was underestimating the effort it would take to remove

the wallpaper, despite my wife's warnings. But when the day came to

remove it, I immediately regretted not simply removing all the

wallboard and replacing it with new board.

Fortunately, I stumbled upon a trick that made the paper easy to

remove. I simply soaked the paper and waited. The plan was to then

try to use steam along with the addition water it had soaked up. After

waiting a few minutes, I found I could actually scrape the paper off

with my fingernail.

Spackling, Sanding and Painting

Spackling and sanding is always a mess, so we masked off the area as

best we could to minimize the dust. Naturally, the plywood and

wallboard were not exactly the same thickness, so my first pass at

spackling was not so great. After a day I took a second pass and

improved my technique enough to make a passable job of it. The

post-spackle sanding was pretty messy when using a power sander, so I

opted for hand sanding after a short while. I then masked the wires

and devices well in advance of painting. Why I did not do this before

spackling I do not know. I guess I think of masking as being just

before the painting, but it would have been handy to avoid all the

spackle and dust that accumulated during the prior steps.

The painting plan consisted of 3 parts:

- primer coat of latex paint;

- second coat of latex paint;

- coat of oil-based, alkyd enamel to the shelf surfaces.

Lighting and Mirror Installation

My plan for the lighting was tentative. I had bought a 16 foot roll of

LED strip lighting, some connectors and a power supply. You were

supposed to be able to cut the LED spool into sections and connect it

up in any way you wanted. I had never done this before so I was not

sure how it worked, or even if I had bought all the items I needed. It

was finally time to see if this would work for my lighting solution.

Since the parts I had were quite spartan, I needed to make some cables

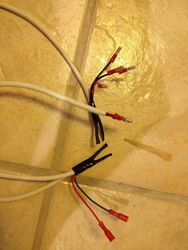

to connect the power supply to the LED strips and to extend the reach

of the power supply. The crucial thing was planning the location of

the lights. I wanted both front and back lighting and I wanted it out

of the way. I settled on a ring around the inside door frame and a

couple strips along the back side of the area with the electronic

components.

And what good is the lighting if you cannot see the back

of the receiver or computers, which is where all the action is? I

installed a few 12"x12" mirror tiles on the back wall to allow easier

connections. I had previously resorted to a hand-hand mirror, but

these proved super useful later on when I got to connection all the

components back up.

I was pleased with the light locations and lighting level, but very

unhappy with the wire locations and the fact that I had "hard wired"

soldered connections. I would redoing the wiring a few days later to

make it easier to plug things in and out and the have the cabling

cleaner.

Fan Installation

After some research, I had located this lice little two-fan package

with a temperature controller that was desired for home theater type

installations. It seemed the perfect solution as it had everything you

would need. Over the coming week I would find out the flaws with this

package. I fully expected to have to play around with the cooling

solution, but I was relatively confident that something with an inflow

and outflow fan would work and I settled on the common size of 120mm to

ensure that I was not constructing the closet around a proprietary

cooling solution.

The inflow fan would be located lower on the back

closet wall, which meant it was drawing air from above a desk that

sits in the kitchen area. The outflow fan would be near the top of the

closet and vent out to the front.

The two-fan package comes with two fans, all the associate mounting brackets, power supply and two thermal controllers. The main problems with this package that I would have to fix were:

- Unless the two fans were right next to each other, the cable between at least one of the fans and the controller needed an extension. I had to custom make a 10 foot extender for the 3 pin fan connector from old computer parts. I wanted the fans to come on as pairs and not be tied to different controller, but to the same controller.

- The controller in the kit come preset to go on at 88 degrees and off at 81 degrees. I found this too inflexible. Even with the closet doors wide open, the temperate at the top of the closet does not go below 81 degrees. This meant that once the fans came on, they were not going off. Luckily, this company sold the exact same controller but where you could adjust the on/off settings. Why this is not part of that package I do not know unless they deliberately do this knowing you'll have to come back for more..

- The fans in the kit are quiet, but only about 40 CFM airflow with low static pressure. I would have to upgrade these to faster fans with 65 CFM.

Access Panels and Final Wiring

With the paint dry on the access panels, it was not time to attached the face-plates, hinges and latches and mount them.

I later changed my mind about where the cable TV and the antenna coax belonged. I originally had them as part of the home theater access panel, but later decided they were really part of the network. Reason for this is that we only have Internet so the cable only needs to go to the cable modem, and the antenna feed goes to the HDHomeRun box that converts it directly to a streaming feed over the network.

Putting it all Together

The upper half of the closet was now ready to have the electronic

components moved into it. The cabinet drawers at this point had just

been painted and would require a week or so to dry before using (due to

using the alkyd oil-based paint).

Computer Install

First to move into their new home were the computers,

which included the last bit of hardware to be installed: the arm for

the computer monitor. There are two servers in here so I used an old

KVM switch and added an old, small LCD monitor I had laying around.

Network Set-up

I first connected all the network cables as they needed to be

logically connected. This brought home the cable management issue

which I knew was coming, but had no great plan for other than some

velcro cable ties. I had allocated 2 inches in the back for cables,

but with all the network cables I really needed a couple more inches

behind this one particular shelf.

Home Theater Setup

Next up was installing the home theater equipment and wiring it up. This

included the Infrared relay and flashers, the HDMI cables and all the

speaker cables.

New Light Wiring Harness

I had been waiting on getting some better cable for the wiring harness

for the LED lights. It came after everything else was assembled, so

that made it harder to install than when the closet was empty of all

shelves and equipment. I thought about waiting on populating the

closet until after rewiring the lights, but I felt that this would be

a good test on how easy or hard it was to run new cables in the closet.

It was harder, but not terrible and I did not need to move a lot of

things to re-wire the lights.

Cabinet Installation

Installing the cabinet and drawers was the last step. You can read more about the cabinet on the Closet Cabinet Project

Page. This was to be the finest moment: when the closet looked like I initially envisioned it...but there was a glitch.

I had forgotten to paint the front part of one of the drawers. I tried

to get the latex paint and the oil-based alkyd paint to match, but they

did not. In some sense this wound up being good because it was pretty

obvious to see that I had missed this area and it might not have been

if they matched better. I should have caught it earlier, but the

lighting in my garage (where they were painted) is not always great,

and some painting fatigue might have set in. Of all the things that

could have gone wrong in the final assemble of the cabinet, this was

very mild and easily correctable.

Project Completion

After allowing the cabinet paint to dry for a week, we put everything

back in the closet and had room to spare. Though we did get rid of a

few things, the main reason we have more space is before the shelves

and cabinet use the full depth of the closet, while the previous

shelves and desk where fairly shallow. Overall, I was pretty happy

with the result as it was very much like I initially envisioned it.

Afterword

The small-ish fans worked alright, but they would struggle to just keep up when things in the closet were going full bore. After a few years, I tried to help the cooling situation with the Server Closet Door Vent Project.

Cassandra.org

Cassandra.org