Story

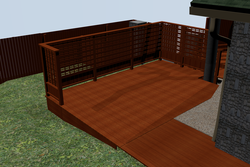

As I was working on the designs and features for the New Decks Project, I found a

general design I liked for a lattice-like wall. The previous deck had

a mostly solid wall around it due to the fact that there was a hot tub

there, which I assume the previous owners did for privacy reasons.

With the hot tub gone, and with some other fence height changes, the

need for a solid wall was diminished. The solid wall made things feel

a little too closed in, so I went for a lattice work design to

provide some visual separation and a little privacy, but not so

militantly dividing the deck area from the rest of the yard.

I now call this the "deck screen", borrowing from Frank Lloyd Wright's

use of the phrase "light screen" for his leaded glass windows. Though

there is no glass in my deck screen, the purpose was identical: providing

visual separation without completely blocking the light/view. Putting

just a little bit of leaded/stained glass in a window creates a

surprisingly effective visual separation from the outside.

The deck screen was part of the original blueprints I gave to the

contractor for building the New

Decks. However, because it was fairly detailed and precise, the

contractor asked whether I might want to build this as he would need to

contract to a "trim guy", who charges a lot of money. This was actually

the best case scenario for me. I was only including it in the contract

work because I thought it might be too complicated for him to coordinate

doing some pieces while I did other pieces. I actually wanted to make it

myself and designed it specically to be a good balance of being nice

visually, but simple to build. Turns out it was fine with him if I did

the work. Thus, I had the carpenters that were building the deck merely

install a few 4x4s and 2x4 as the structural skeleton, and when they were

done, I added the trim work and lattice work.

The original design had a lower section of vertical slats, but since

the Deck Furniture was mostly

going to be covering the lower portion of the deck screen, this seemed

like and unecessary extra complication, so I decided to make it

uniformly the same from top to bottom.

Details

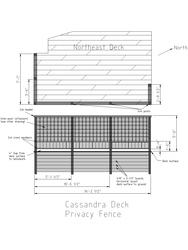

The contractors that built the deck just left a frame for me to add the

deck screen to. The frame was six 4x4 vertical posts with 2x4 cross

members mounted flush to the posts. One span between the posts was too

long (7 feet) and they needed to add a support in the middle. My

orginal plan called for an extra post, but I did not catch it in time

and it would have been a lot of extra work to add it by the time I

noticed. The pictures above are what the frame looked like before I

began my work on it.

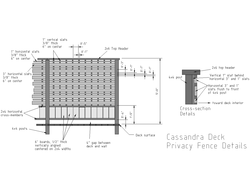

An important design feature is the 4 inch gap between the deck surface

and the beginning of the deck screen. With the previous wall, which went

all the way down to the deck surface, debris removal was a problem. This

was especially true trying to use a leaf blower. With the corners,

blowing the leaves would result in a cyclone of leaves, mostly falling

back down onto the place where they started. With the added gap, we can

just blow or sweep leaves and debris off the deck into the yard area.

I had begun building the deck screen in my garage before the deck was

finished and before the frame structure of this was even up. I had

rough dimensions of how high and wide they would be, but could not

commit to the final dimensions until the carpenters had finished their

work. Thus, I made them oversized, and would trim them to their final

size with a circular saw once the deck was completed. Each night when

the contractors finished, I would measure the dimensions to ensure that

everything was tracking to the sizes I was expecting.

Final cutting and installation would reveal that one of the 4x4 posts

for the deck screen was fairly non-square. This turned out to be less

of a hassle than it usually is to compensate for uneven structures.

Thus, one of the deck screens is really trapezoidal shaped, though you

have to look very closely to notice it. The 7 foot wide section of

deck screen probably should have been two 3.5 foot sections with an

extra 4x4 post in the middle. It was challenging to assembly and

manuever the 7 foot section around the garage.

The trim for the deck screen was done with Ipe wood, which is the same as

the deck material. A lot of this I was able to grab from the scrap heap

after the carpenters were done with the deck planking. The lattice part

was done with 1x4 cedar planks (one side finished). I ripped some of this

into 3 inch strips and some of it into 1 inch strips. The horizontal

pieces are alternating 1 inch and 3 inch pieces, while the vertical

pieces are 1 inch pieces. I used special tan deck screws to hold it all

together. The cedar wood I used, though finished on one side, was not of

uniform quality, so I had a little more waste than I expected, and had to

sand the front side surfaces to both smooth it out and clean it up from

other surface blemishes.

The Ipe wood trim work was not really part of the design and was a very

late addition. I had wanted everything to be Ipe, including the deck

screen, but a 4x4 piece of Ipe wood is hard to come by, and also very,

very pricey. I did see some mention of just using deck boards to add a

facade to the 4x4, so I had that in the back of my mind. What really

made it all come together as a solution was trying to work out a clean

way to install the deck screen, given there were not good surfaces to

directly screw into. By installing the Ipe trim work, this gave me a

simple and visually appealing way to adhere the deck screens to the

structure. Figuring out how to mount these without adding too much

complexity or ugliness was the most difficult design problem and I did

not actually decide on this until after the deck screens and frame were

finished. The end result was simple, but there were a few more

complicated designs for affixing the deck screen that preceeded this

that I was never quite happy with.

I had to first install the front trim pieces, then the deck screen

lattice work, and then finally the rear trim. The front trim is what

the screen would screw into by just sliding it in the back side and

screwing around the edges. The rear trim would make the opening

smaller, so had to be done afterwards.

While building and installing the deck screen, we had not decided

exactly what type and color of finsh to make it. After seing the deck

screens in their "raw" state, I really liked the contrasting light and

dark colors, so we went with a semi-transparent cedar stain that would

protect the wood but not change the color very much (Behr

Semi-transparent Weatherproofing Wood Stain, Cedar Naturaltone

No. 5533). Having to stain it after assembly made this a very tedious

job. Probably took 20 hours total to paint due to all the nooks and

crannies the assmebled lattice work had. Had we known the finish ahead

of time, it would have been a lot easier to stain it prior to assembly.

Final Results

Cassandra.org

Cassandra.org