Story

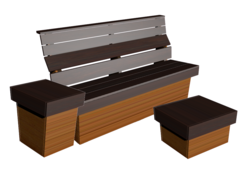

As I was researching for designs and features for the New Decks Project, I really liked

the decks I saw that had built in furniture: benches, tables, planters,

etc. My original designs had such features but a few things conspired

to make me opt for stand-alone furniture:

- I started to get very particular about the geometry of the benches and tables for maximal comfort;

- I started wanting a lot of benches and tables;

- I decided to contract out the structural deck work;

- I worried about not getting things built exactly as I wanted;

- I worried that this would probably ad a significant amount to the cost;

- I liked the flexibility of being able to move the furniture around, even taking it with me if I ever had to up and move, or just moving it if I find a better layout;

In the end, this first phase consisted of building the following pieces:

- (4) benches;

- (3) narrow side tables;

- (2) wide side tables; and

- (3) ottomans.

Ergonomics and Prototypes

I wanted a lot of bench seating, and I wanted it to be comfortable

seating, so I spent a fair amount of time looking at designs and

researching seat ergonomics. The two most influential sources were a

rough bench design sketch I found via Google (see

here), and a PDF file from an office chair manufacturer on seating

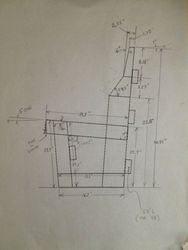

ergonomics. The dimensions of the bench design image were not crystal

clear, and the size of the lumber was larger than I liked so I adapted

this general pattern with the preferred lumber sizes and researched

dimensions from the office chair company's PDF.

Good office seats have many adjustable components because good

ergonomics are dependent on a person's height and body dimensions. One

size does not fit all. Since I was not going to make adjustable deck

benches, I had to find a good compromised of comfort for the varying

sizes of people. Not knowing if the compromise dimensions would work,

and having some spare wood in my garage, I decided to make a prototype

bench before committing to the final bench dimensions. It was more a

chair than a bench, due to the length, but it had the same ergonomic

profile. This turned out to be an invaluable exercise. I found that

just a half inch difference in the height of the lumbar support

inflection point would be the difference bewteen a completely

uncomfortable chair and a very comfortable one. The prototype allowed

me to avoid building uncomfortable benches.

Another important part of comfortable leisure seating (for me) is

having armrests. It is usually bad to have armrests for a computer

chair, but these were for relaxing not typing. I also wanted table

space and so had the tables interspersed with the benches to serve both

purposes, as the height of a side table and the height of an good

armrest is just about the same.

I also wanted some ottomans for putting your feet up, as well as low

coffee table-like surfaces and it turns out both these would be the

same height, so I made pieces that could function as either, with the

added side effect of it also being an alternative (albeit lower)

seating option if someone was so inclined. Good seating for kids too I

guess.

Early Designs

The benches needed to be long-lasting and weather resistant as well as

easy to build. I originally was going to use all pressure treated

lumber with stainless steel screws. I would then paint/stain them to

match the deck, which at this point was going to be something near a

mahogany color (it would change to be Ipe). As I do with all my

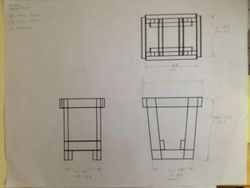

woodworking projects now, I begin by sketching in pencil, and once I

have a rough idea, I model them down to the individual pieces of wood

on a computer (using the fabulous Blender software. At right, you can

see the original plans. This allows me to refine the ideas and begin

to visualize how the fasteners will go and how I can best assemble the

work.

I had planned to make one of the benches follow the angled contours of

the deck/fence for one placement, but I abandoned this when I did not

want to add complexity to the design and wanted to avoid

special-purpose pieces. Thus, all four benches are identical size and

shapes, which simplified the building process considerably. I found a

good compromised size (5 foot length) that would work in all the

planned locations.

Final Design

The basic design I originally came up with stayed mostly the same, but

there were a few important changes I made before arriving at the final

design:

- Only using pressure treated wood for frame and nicer woods (Ipe and Cedar) for all visible surfaces;

- Moved the infection point for the lumbar support 1/2" lower to accomodate shorter people more comfortably;

- Angled in two sides of the table to match bench angle for consistency of design and to prevent the tables from being too blocky;

- I added a lower "skirt" of cedar planking to hide the frame and give a cleaner look that would match the deck area fences; and

- I used Ipe wood to match the chosen deck material for the wearable surfaces (the seat and back).

Blueprints

One of the annoying things about making a 3D model on the computer is

that it is not very good at producing working blueprints that I need to

print out to work with in the shop. I need to know precise dimensions

of the important pieces when I cut the wood and do not want to

constantly be having to refer to the computer model.

The best solution I have now (and it is a bad solution), is to do the following:

- turn the model into a "wire model".

- render it setting the camera to use an orthographic projection.

- save the rendering to an image file.

- repeat this with the camera pointing in the 3 major axis.

- gather up the 3 rendered images into a single image (I use Gimp).

- print the image.

- manually add the arrows and dimensioning I need with a pencil.

- turn on edge length displays on the model and fill in dimensions cross-referencing with the computer model edge lengths.

Planning and Wood Purchase

I needed a lot of wood and of 3 different varieties:

- Pressure Treated Pine: for the structural frames;

- Ipe: for the wearable surfaces to match the deck boards on the New Decks; and

- Cedar: for the lower skirting that hides the clunky frames.

So how does one know how much wood to order? One has to do a lot of

work planning it. I first enumerate the individual pieces I need to

cut, from what stock I will cut it, and how long apiece I need. Then,

after finding out what lengths of stock the lumber yard stocks, I begin

to layout the pieces on the standard sized stock, thereby counting up

home many of each I need. Naturally, I needed to add some extra for

waste and unexpected happenings.

With a final count in hand, I go to the lumber yard, pick out the

lumber and arrange delivery. When the delivery comes, then I had to do

some serious planning to find a place for it in my shop (a.k.a.,

garage) in such a way that I could work with it. Carrying all that

lumber from the driveway into the garage was quite a workout as well.

The Ipe is quite heavy, especially in 16 and 20 foot boards, and the

pressure treated lumber in 16 foot lengths is not too light either.

Shop Preparation

Being able to handle and cut very long (some 20 feet) lumber required

some thought. I needed to be able to get at the lumber, move it to the

miter saw, but also be able to cut something on the table saw if I

needed. It got even trickier when I had a combination of cut pieces to

store and uncut stock. Things were wuite cluttered for a while. I

have two 8 foot tables that I put on each side of the miter saw which

allows me to cut the long stock, but only if the garage door is open

and it hangs out.

First Table

By building the protoype bench, I had worked out the details of the

sizes of the pieces and how to assemble it. But the tables and

ottomans were nothing but a concept at this point, so before I went and

cut all the wood for all the tables, I wanted to first build the frame

for one table to ensure I had the right dimensions and figure out how

to assemble it. DUring this process, unforeseen things can come up and

cause slight redesigns (as it did with the bench). The narrow table,

wide table and ottoman all had the same basic structure. They only

varied in a few dimensions. Thus, knowing how to assemble any one

table would give me enough confidence to know how the others would go.

First Bench

Though the prototype gave me good confidence in having the righ sized

parts, assembling a 5 foot bench would require some tricker setup than

the narrow width prototype did. Thus, I wanted to get one bench frame

assembled to work this out. Again, something could come up that causes

a design change to help with assembly. In fact, I did modify exactly

where I was putting the cross-pieces to provide a more stable

structure.

Bulk Wood Cutting

With no more uncertainty on the part sizes and assembly to worry about,

it was time to cut up all the lumber into the parts I would need for

the total of 12 pieces of furniture.

Lots of stacks of parts piled up quickly and it was a challenge to find

surfaces to put them on.

When the sawdust settled, here's what all the parts looked like.

First Oiling, Staining and Painting

By this time, I had assembled the frames for one of each type of furniture. Though the frames were pressure treated lumber and mostly be hidden from view, I wanted to paint them because:

- I wanted the cut ends to be better sealed to last longer; and

- though mostly hidden, the gaps in the planks would allow you to see the frames a little, especially if the color was a constrasting light color like the frames were.

Ipe wood, though heavy, hard, strong and long-lasting, has the habit of

"checking, which is the ends getting little splits in them over time as

they dry out. To prevent this, you can use a special end-grain sealer

on them, which I did.

The rest of the Ipe was treated with an oil finish (Ipe Oil) which

helps protect it and brings out a very nice color to it. The cedar,

though generally weather resistant, I chose to stain with a sealer that

would greatly extend their lifetime.

First Bench

With the frames painted, the Ipe boards oiled and the cedar planks

stained, all that was left was the assembly. Actually, at this point,

all that was finished were parts enoughn to make one bench. The pkan

was to paint, oil and stain parts one furniture piece at a time. This

interleaving would help break up the monotony a bit as well as get some

finished products before worrying about geting through all the

painting, oiling and staining.

There was only some additional assembly things to be worked out. Though

the assembly of the frames for everything was figured out, putting the

cedar planks and Ipe still had some unknowns.

The trickiest assembly clamping issue came from one of the seat back

boards of the bench, whcih lies on a weird angle. Luckily, I had not

thrown any of the wood scraps away and I could use the cut-away pieces

from the benches that matches the angle.[ I had to trim them down a

little to allow for installing a screw, but generally the moral of the

story is to not dispose of any wood scraps until the project is

finished.

Getting the first bench completely finished was a big milestone. We

were going away on vacation and the goal was to get one bench done

before we left. We made it by a day or so.

One part I had not made yet was an upper side cedar skirt piece. I was

not sure I would need to add this, but after assmebling it, it became

clear that it looked very odd without it. Thus, I went and cut the

necessary cedar for the 4 benches.

First Table

I still needed to work out the assembly of cedar and Ipe boards for the

tables, so did this after painting, oiling an dstaining a set of boards

for a table.

First Ottoman

Though the structure of the ottoman is identical to the tables, it's

short height changes a few things in subtle ways. Thus, the next batch

of parts prepared were for an ottoman to work out all the assembly

details for it.

Bulk Oiling, Staining and Painting

Because of my hectic travel schedule around this time, it turned out to

be best for me to just be oiling and staining parts for a few days.

Though I did this one piece of furniture at a time, I was not

assembling any more pieces until all the oiling and staining was

completed.

Like most woods, Ipe changes color drastically when an oil finish is

applied. The oil finish does have somem pigments in it to protect from

UV rays, but generally, if you just wet the Ipe it takes on a color

much like what is shown here after it has been oiled.

Bulk Frame Assembly

With the painting, oiling and staining done, I decided to do the

assembly more like an assembly line. Main reason for this was the

minimize context switching, changing tools and to do it while it was

fresh in my mind.

Each bench requires 3 side assmeblies, which are joined by 4 cross

pieces. The way they were designed, 2 of these 3 are identical, while

the other is a "left hand" version. This allows the right type of

surface to fasten the cedar skirting to. I had a great fear of not

making the right amount of each type of bench sides.

Bulk Final Assembly

With all the frames assmebled, it was time to put on the cedar and Ipe

planks for the final assembly. I also did this one furniture piece at

a time.

I put all the ottomans together first, then moved onto the tables,

saving th8e benches for last.

I did the benches last because they were easier to do with two people

and my wife was out of town during this point in time. The benches

also take up the most space, so I delayed putting their frames together

until after I cleared space by assembling the other pieces.

Ipe is a very heavy wood. Between that and the ample frame structure of

pressure treated lumber, a finished bench weighs quite a lot. I would

estimate it weighs near 200 lbs. Thus, having a helper as it gets

assembled makes it much easier.

Assembly Completed

It was nearly two months from when I ordered the lumber until all the

furniture was finished. One month of that I was traveling, and I was

also doing some other projects during this time, but the shop/garage

was dominanted with this project for a solid 2 months. Thus, it was a

good feeling to finally see it all realized.

I needed to hold off on putting the furniture on the deck because there

was still some fence painting to be done and some light wiring to be

done. Thus, for a few days the furniture was just stacked up in the

shop/garage.

Final Result

Once the miscellaneous tasks on the New Decks Project were completed,

we could put the furniture where it was intended. This stuff was very

heavy so needed some furniture dollies and help to get it all in place.

Cassandra.org

Cassandra.org