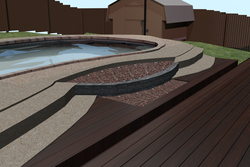

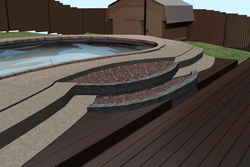

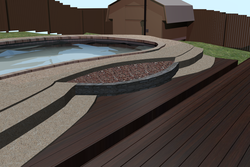

Story

While designing and planning the New

Decks for our house, I eventually decided to simplify the project

by not worrying about the complicated geometry around the curved stairs

that go up to our pool. You can see this area in the images at

right. The new (northwest) deck added by the steps is just a plain

rectangle, which left a weird "no man's land" between it and the pool

steps. The desire for a new deck section at ground level also left a

weird gap between the ground and deck on the entire perimeter that

needed to be figured out. Complicating this was the need for a very

efficicent drainage in the area. When it rains hard, the area going

into this new deck and under it becomes a fast flowing river. It is

essential that water continue to travel unimpeded through here, or else

the backed-up water will enter the house.

Stairs and Planter Abandoned

During the construction of the New

Decks and for many weeks afterwards, the working idea for the area

was to add some planter section to this area, but it also require some

stairs or platform to transition to the stairs. I very much dislike

having to comes from the pool to the deck and having toi step over

something or step into dirt/grass/mud.

The odd geometry, the rock-hard ground, the existing structures and the

desire not to make this too complicated made designing this

confounding. I came up with some solutions that just did not seem

worth the effort. I decided I would probably never do something this

complex, so adandoned this and went searching for some very simple

shorter-term solution. Here's some 3D model renderings of the

progression of the abandon idea of adding stairs and a planter to this

area.

Large Rocks Installation

Before settling on a solution for the oddly shaped area, we had a more

pressing need to come up with a way to fill in a 6 inch wide and 8 inch

deep gap between the ground and the new deck. I did not want to fill

it in with dirt because that is bad for the wood, and it would not

solve the drainage issue. I decided I would use large stones in a kind

of river-bed look. The west end of this deck is where a large volume

of water enters at ahigh rate when it rains hard, so this would need a

larger area for water passage.

We went out to stone supplies to look at various large rocks, and

settled on something that was not too expensive, but looked decent.

Estimating how much we needed, I thought it was about 1/3 of a cubic

yard, but to be safe, we ordered 1/2 a cubic yard. This cost us $30 for

what they called "5 to 7 rock", which referred to their size, but there

was a lot of variation outside that range.

The delivery charge for the $30 worth of rocks would have been $45 and

the guy made it seem like a simple process of just making a few trips

using buckets, so I decided to do that. Worried about how much weight

my little car could take, I asked the person that moves the rocks

around about how much a 1/2 cubic yard weighs. He said it weights

about 1,000 pounds and that people ususally do it in two trips. I

gathered up buckets and milk crates and put what I thought was plenty

of weight in my car for the first trip. I definitely would not have

wanted to put in more. It wound up taking me 4 trips and was a royal

pain. I also had this thought on hauling the first heavy load that for

the sake of saying $45 on the delivery charge, I was risking a

multi-hundred dollar car repair. I should have paid for the delivery.

Hauling all these rocks around was a lot of physical work, so having

the wife to help was very useful. The end result was not as appealing

as I hoped, but way better than what was there or any other idea I

could think of. Note that we put some landscape fabric underneath the

rocks, both the prevent erosion and weed growth.

Ground Cover Addition

There were some bare, graded areas that we decided to shore up with

some ground cover. This was meant to prevent erosion and to liven up

the area a bit. The wife had some good ideas on this for plants that

did well in out climate and they looked very good adjacent to these

rocks.

Stepping Stones Idea Escalates

For the grassy/dirt area between the new deck and the pool steps, my

simple idea was to lay down a few paving stones to act more like

stepping stones so one could move from the pool to the deck without

stepping on dirt/grass. We bought a bunch of paving stones for this

purpose, and I figured I would just lightly level the area and lay them

down.

I layed them out top see how many total I would need and get an feel

for how it would look (see right). As I sat staring at this, the whole

idea became very unsatisfactory both from a visual look and from a "not

done right" point of view. I finally decided if I was going to put

that many paving stones down, I should do it the right way. What

preventing me from wanting to do it the right way to begin with was the

prospect of having to excavate the entire area 7 inches deep. The

ground is severely hard and very rocky. Still, I decided I would

attempt it, see how it went and hoped for the best.

Excavation

The first unpleasant fact of choosing to excavate the area for paving

stones was having to undo the placement of all the large rocks along

the entire area. I co-uld not just place them on the side as they

would just be in the way, so I had to load them into buckets/baskets

and put them out of the way.

I then began digging out the area. It was slow going at first because

I quickly realized that I did not have a lot of ground digging

experience and was very inefficiently going about it. I quickly

learned some tricks that made it much more bearable. The main

(probably obvious) trick was separation of breaking up the ground with

the removal of the dirt.

Even as I was beginnning to dig the area out, there was an important

problem that I had no good solution for. It would be for all the

dirt and sand needed for the pavers to run right up against the deck,

both due to drainage and rot concerns. How would I be able to

provide a stable base for the pavers, while needing the sides to be

not dirt and permeable? I did plan on replacing the large rocks next

to the deck, so that was part of a solution, but that alone would not

be enough to prevent the paver base material from eroding away.

My plan was to work on this project the first half of each day before

it got too hot (it being August in Austin). I took the afternoon to

head to Home Depot to both get some supplies and browse for ideas on

how tro solve the problem of holding back the paver ground.

Ground Preparation

The second day I continued the excavation until I got the whole area to

a depth that I thoughtn would be a good start. The I needed to get out

the levels, , mason string and stakes to get more accurate measurements

of the depth of the areas. The picture on the right makes it look very

professional, but in fact this was very amateurish. Because the ground

was so hard, rocky and dry, I could not get the stakes in very well, so

the line was not very taught, level or stable. I felt like there must

probably a whole technique to using stakes, mason line and level that I

had no clue about. Still, this gave me enough of arough idea of the

level across the whole area, and I found it very uneven. Some places

were deep enough already, but some needed a couple more inches taken

off it. At this level, the ground was very hard and very rocky, so a

lot of effort was expended in removing those extra 2 inches.

Some additonal complications arose. The first was relatively simple to

address: buried sprinkler lines. These I had always thought to be

defunct, disconnected lines, because a sprinkler head attached to them

never worked. With the ground opened up around it, I decided I would

verify this theory by turning on the sprinklers. Though water did not

come gushing out, there did develop some dampness, indicating that the

lines were only mostly dead. A thoery is that the concrete stairs

shifted over the years and might have pinched the line somewhere. Not

wanting to risk the line suddenly freeing up and pouring lots of water

under the paving stones, I needed to cap these lines as a precaution.

The more impactful complication was due to the concrete structure of

the pool stairs. It seems like it has a few footers that spread out

from the base to provide a wider footprint. This put a limit on how low

I could install the paving stones since they would be in the way. I

did not mind if the base material here was thin, since it was a small

area, but it also meant that the paving stones top surface would have

to be higher than the deck if I wanted to completely hide the footer.

I would eventually compromise on the height of the paving stones. My

desire to have them at the same level as the deck, and my lack of

desire to haul any more 40 pound bags of base material would rule the

day. Adding another inch of base material would mean another trip tom

the store, and lugging around another 4 to 5 bags around. Thus, the end

result is that you can see a bit of the step footer and I was not able

to put any paving stones in that area.

With everything excavated, the next step was to put landscape fabric

over the entire area (and running a few inches under the deck) to

prevent weed growth, but allow drainage. This is standard fair as the

bottom layer for paving stones. What was not common was what came next.

The solution I settled on to prevent the paver base layers from

creeping under the deck, and to hold the material in place was a three

pronged strategy. This was 50% my idea and 50% credited to an

unusually helpful person I talked to at Home Depot. I bought some

aluminum window screening as the first layer, which would be backed up

with rocks too large to fit under the deck. I then would add a layer

of smaller rocks (river pebbles) next to the larger rocks so that the

paver base material would (hopefully) be held at bay by this.

It was somewhat interesting that I could not find any definitive answer

to how to best solve the problem of this paver stone to deck

transition. I spent many hours hunting around the web, reading paver

stone how-to guides and watching numerous videos. They all assume you

have a flat area and want to just carve out a setion for the paver

stones. I have no idea whether my solution will work or not, so only

time will tell. I give it a 50/50 chance of lasting 5 years.

Note that the smaller rocks will not be visible in the end. These only

go as high as the base layer dirt/rocks and afterwards, the large rocks

(only) will be replaced where they began. This ensures a uniform look

of the large rocks around the perimeter.

Paver Base Layer

With the ground fully prepared, it was time to start building up the

layers for a stable paver installation. The first layer is the "base",

which everyone says should be 4-6 inches of crushed gravel. When I

went looking for this at Home Depot, I did not find it anywhere. But I

did find a product called "paver base", which looked very gravel-like,

so I assumed this was a good substitute and specifically made for

pavers. However, in the end, I think this was a mistake. Some of the

bags looked like gravel, but some of them looked more like sand (see

pictures at right). I wondered if a mix of gravel and sand was ideal,

since once you put the sand on top of the gravel this is what you get

anyway, so this product just premixed it.

I had hoped the finer looking paver base stuff had gravel insided, but

for the most part, there were very few rocks in many of the bags. I

wound up needing more than I originally bought, so went to Lowe's to

see what they might have. They too lacked gravel, but also had a

"paver base" product, though theirs looked much more like gravel. But

even their bags had wildly different textures. I bought two types of

paver base and wound up with 4 different colors and textures.

Weird. What I decided to do was to put the more gravel-like bags in the

higher traffic areas and at the bottom. The more sand-like bags I

reserved for low traffic areas and the upper parts of the base layer.

As per proper paver base installation, after adding every 2 inches of

paver base, this had to be compacted down with a tamper. Not having

one, I thought about using a small sledgehammer and some blocks of wood

for this. This might have worked, but since a tamper was less than $30

and since there are other ground improvekment projects on my list, I

invested in the proper tool for this. I was very glad I did as it was

much more effective and less effort than my home-grown solution would

have been.

I had to remove the layout stakes and mason line to work on the ground

preparation, though they were of limited use due to my not being able

to anchor them well enough. But now I needed to level out the base

layer to be even and consistent across the whole area. Because the

deck itself runs across the entire area, and since I assume the

carpenters made this level, I decided to use the top of the deck as the

reference point, and I rigged up some wood pieces to help measure the

level relative to the deck surface. The idea was tro rest one end on

the deck and run it across the paver area to both evenm things aout and

measure against it. k It was at this point, seeing where the level was

after adding 12 bags of paver base that I decided to lower everything

by an inch.

Note that the deck itself is not completely level. It has some up and

down waves to it. Not terrible, but if you look closely yo-u can see

the rises and falls. As such, the final paving stones have the same

contour. Maybe this is better. Had the paver stones been true to

level, it might have highlighted the uneveness of the deck.

Note that when all was said and done, I added 18 bags of paver base,

which is equivalent to 7 cubic feet. The total area to be covered was

only 22 square feet.

Paver Sand Layer

On top of the 3-4 inches of base, one should at about an inch of paver

sand and level this off well. The traditional ways of leveling it

would not work due to the geometery and obstacles, so I just used an

adaptation of the base level tool for the sand leveling.

I wound up making three trips for bags of paver sand. Some of these

were to Home Depot and some to Lowes and the different between the two

were quite stark as the pictures show. The Home Depot was very

sand-like, while Lowes was finer, more clay-like. I have no idea which

would be better, but I decided to put the finer Lowes product on top.

Covering the 22 square feet of area to 1 inch deep in paver sand took 4

bags, which is 2 cubic feet. Note that while Home Depot's bag specify

the bags as being 0.5 cubic feet, at Lowes. the bags only give their

weight: 40 pounds. This is horrible of Lowes. Yes, the weight is of

interest, but everything you need to do to plan your project is done in

cubic feet or yards, not weight. Luckily, I knew from Home Depot that a

bag was 0.5 cubic yards, and the Lowes bags were about the same size.

Paver Edging

Adding some form of edging to pavers to hold them from migrating

horizonatlly is always recommended. There are lots of ways to achive

this, depending on the application. The edging also give the final

result a cleaner looking finish. I decided to use the more traditional

plastic edging, where you use stakes to hold it down. I was a bit

skeptical how well these stakes would hold, but I was at a loss for any

better edging method in this situation, so I hoped for the best.

The large rocks would be filling in between the deck and the start of

the paving stones, so I measured the width of the rocks in the area

where I did not have to remove them, which was about 7 inches. It was

very frustrating to install what should have been a very simple job. I

had plenty of stakes, and the plastic rails had plenty of holes to put

them in. Either the ground was too loose to secure them, or I would

hit a rock and not be able to drive the spike in. More than half the

locations I tried to put a spike in I hit a rock and had to pull it

out. The few locations I was able to get a good grip into required me

to hit the spike hard enough that the entire rail had shifted by the

time it was in. I wound up with a completely non-straight edge. I had

to pull up spikes and do the best I could to get this back to

straight. I eventually had to settle for "mostly straight".

Paver Installation

I got to the point of being ready to install the paving stones around

2pm on the third day of the project. It was pretty hot out (let's say

99 degrees as it usually is by this time) and I was a bit tired, but

the end seemed in sight, so I pressed onwards in hopes of wrapping this

project up that day.

Due to the weird shape of the area, I would need to cut the paver

stones to fill in the gaps. The proper way to do this is with a

masonry saw, but since I do not have one, I would have to buy or rent

one. This was a line I would not cross for this project. It was

already a bigger project than I originally planned, so I opted for the

poor man's method using a chisel. I first wanted to lay out all the

full-sized stones first before trying to split any of them. I did the

layout trying to minimum the number of gaps I would need to fill in.

Once all the full stones were in place, I then got a chisel and

drilling hammer and attempted to split the bricks into shapes. This

was only semi-successful. At first, the stones would randomly split

and I would hope to be able to fit them somewhere (since there were so

many opportunities). As this went on, I got a little more skilled at

this and had a few that split where I wanted them to. However, in the

end, I opted to just leave all the small areas since I was not able to

get precise enough control over the pieces by the time I ran out of

pavers. I fear regretting this decision someday.

After laying the paving stones down, the nextstep is to tamp them down,

and then fill in the gaps withn paving sand. You do this by just

dumping sand on top and using a broom to work it in between the gaps.

After this, you wash off the excess.

Final Result

The last steps were to re-install all the large rocks between the deck

and pavers, clean everything up, put the tools away and have a beer.

Cassandra.org

Cassandra.org